For today’s class we had the guest lecturer Anastasia from Fablab Barcelona give a really wonderful talk, thinking about materiality & sustainability. More soon!

Becca's ITP Sketchbook

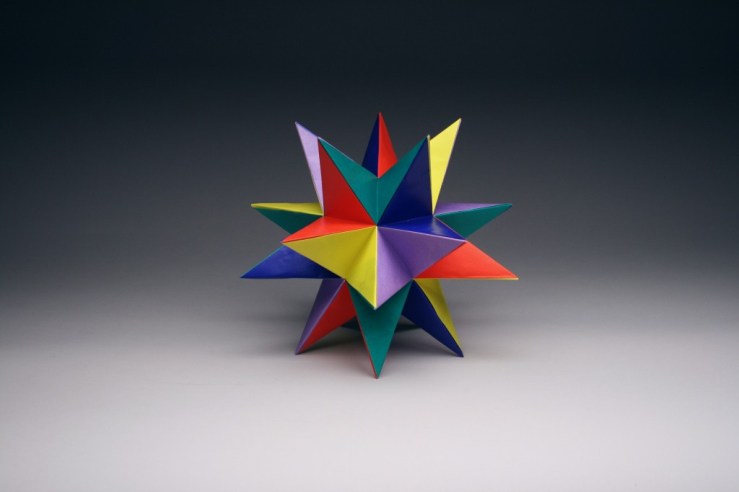

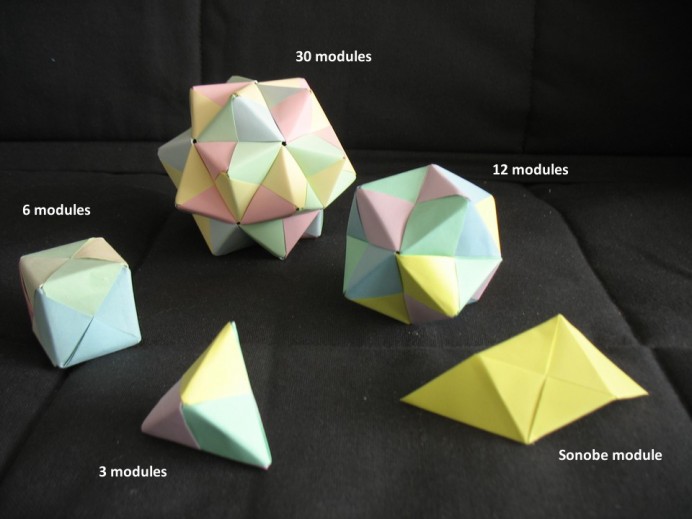

Initially Inspired by this Robert Lang Elevated Icosahedren

[Above Image is from the blog Philodendron / the post Modular Paper Art]

After doing some more digging I found my self really attracted to these modular color study wall art / paper studies. Would like to try and recreate as a puzzle verses more of a wall art item ❤ Philodendron’s post was initially inspired by Design Sponge’s post here

Thinking about color studies:

Apr 19 6:30pm – 9:00pm

Twist together fibers to form yarn

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth.

Knitting creates multiple loops of yarn, called stitches, in a line or tube. Knitting has multiple active stitches on the needle at one time.

Crochet is a process of creating fabric by interlocking loops of yarn, thread, or strands of other materials using a crochet hook.

Quilting is the process of sewing two or more layers of fabric together to make a thicker padded material, usually to create a quilt or quilted garment.

Embroidery is the craft of decorating fabric or other materials using a needle to apply thread or yarn.

Screen printing is a printing technique whereby a mesh is used to transfer ink onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

Dyeing is the application of dyes or pigments on textile materials such as fibers, yarns, and fabrics with the objective of achieving color with desired fastness.

Hw: Cast a Bibenda – Simple Pneumatic Bending Actuator

Image Credit: Image the Western Australian Herbarium, Department of Biodiversity, Conservation and Attractions (https://florabase.dpaw.wa.gov.au/help/copyright).

“Newly-classified in 2007, Tecticornia Bibenda is a unique succulent native to Western Australia, and has been recognized as a plant particularly worthy of conservation and continued research. Its segmented stem frequently prompts comparison to the Michelin Man. The Bibenda Actuator’s relationship to this plant extends beyond the nod to the segmented bulbous shape, finding bio-inspiration from the mobility of plants, which move via hydraulic manipulation while most animals use muscle contraction. Usually plant hydraulic motion occurs as tissue-level adjustments of fluid (primarily water): for example, with the inside of a curve having less fluid, and the outside more. ” [chapter 10 Make:Soft Robotics ]

This weekend a few of us that were on the floor at the same time decided to join forces when we couldn’t find the right PVC size reserved from class (and after trying a local hardware store <3). Rachel, Madison, Gabriella & I went through the Bibenda pneumatic actuator tutorial round robin style, taking turns with each step / making sure we each understood & tried out all the tools. Matt was also in the area and reminded us how the Vacuum worked. Arnab who was in the room working on another project mentioned how he was excited to see the vacuum and that he had actually tried to make one himself one time. He mentioned that cellophane could be a good alternative as a material to help with future Silicone mold experiences.

Lessons Learned:

(pictures throughout process with Rachel, Madison & Gabriella – & a thank you to Matt for reminding us how to use the vacuum! We ended up using the remaining PVC from Matt & Ashley’s endeavors. We think either the class had already used the amount designated for the exercise, or maybe it had accidentally been placed into the junk shelf area after a previous group <3)

(Gabriella showing pix post removing from mold)

( learning how to use the Vacuum for the degassing stages)

(Madison pouring the A+B mixed Eco-Silicone mix into our mold from a distance to help with air bubbles)

(Rachel weighing & pouring the A+B mixture)

“This pneumatic bending actuator doesn’t have a specific job, but it’s a very good demonstration of how you can create a complex system with a minimal number of simple parts. It also serves as an on-ramp for working with cast silicone for robotics. The Bibenda can be cast in an afternoon, and its size and shape allow for bubbles to easily escape to the top for a clean casting. Another feature is the ease of demolding, which can serve as some early practice as you proceed to the more elaborate projects later in the book. This project can also be hooked up to the air power supply to be controlled digitally, or with a jumbo syringe filled with water to evoke the hydraulic motion of its namesake.

This design highlights the capabilities of using fabric to vary the amount of elasticity. By embedding fabric into the silicone to limit the stretch, we create zones of greater and lesser inflation. You can check out this concept as applied in RBO Hand’s PneuFlex actuators, where this kind of constrained area is referred to as the “passive layer” and includes embedded porous fabric. The PnueNet actuator developed by the Whitesides Research Group at Harvard takes advantage of what they call the “differential strain” effect to help achieve motions such as bending and twisting by using a paper layer to cause more rigidity. Similarly, a collaboration between UPenn and Cornell yielded an octopus-like skin by including fiber-mesh rings to make dynamic multidimensional motion.” – Chapter 10 Make:Soft Robotics

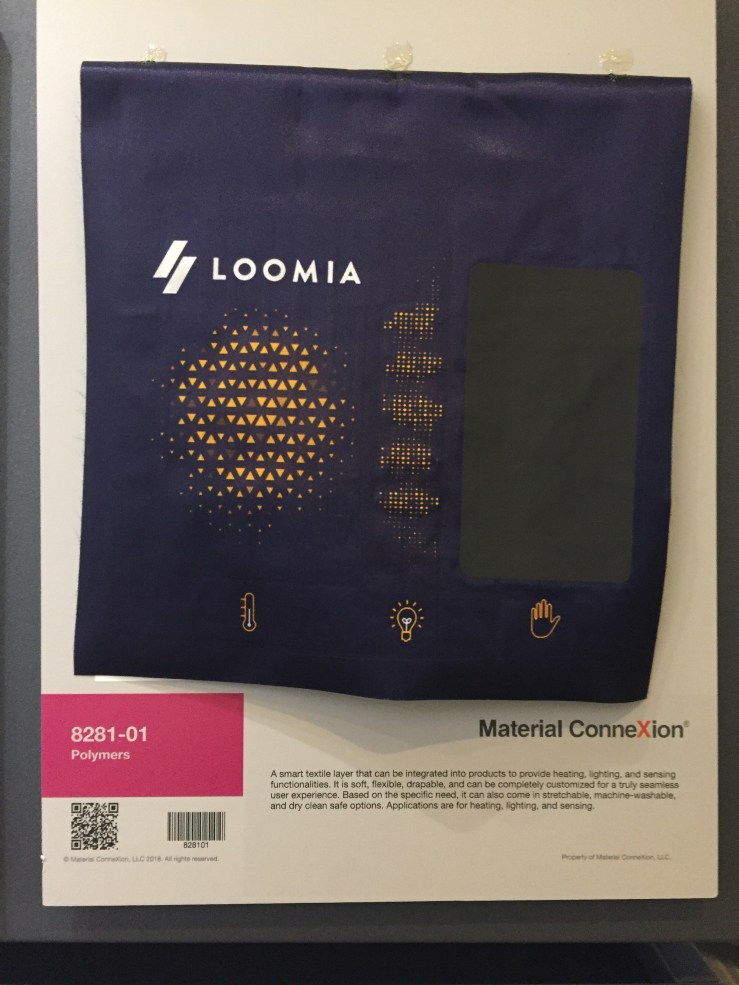

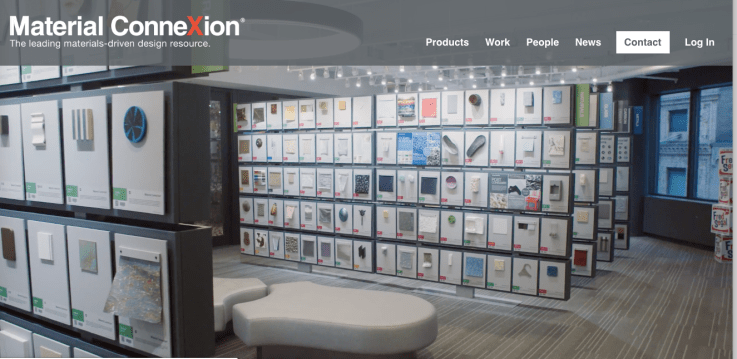

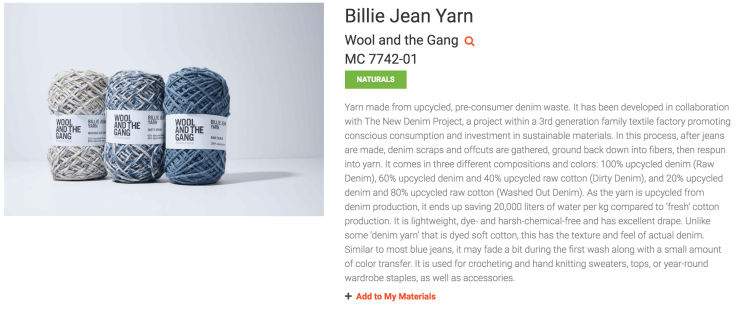

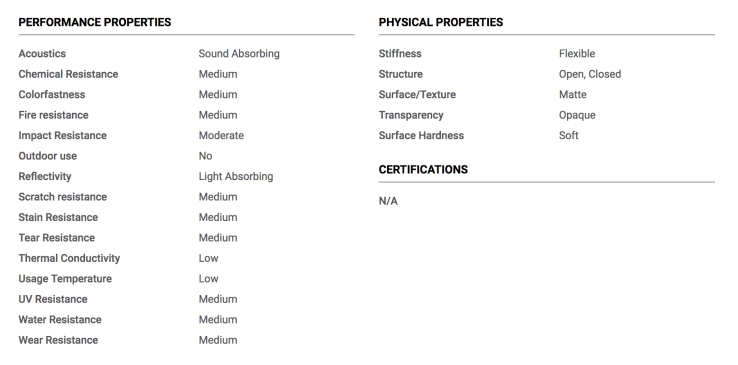

This past Monday we had the great experience of visiting Material ConneXion! and their sustainable materials library . It was such a great experience and perfect complement to our Wearables W9 class (Manufacturing + Crafting) that night as well where Loomia came in to talk us through their process. I was attracted to so many materials, and really after signing up for the student account got lost in their Material Library archive for a handful of hours. What a mindblowing resource! Around 8000 material items to learn from in their digital archive. I found myself tending to be attracted to materials that:

Soft Robotics & Wearables class have been complementing eachother in really nice ways. After our Wearables make up class on Friday covering various soft sensor crafting techniques, felt excited about reaching out to sources through Material ConneXion’s database for samples for knitting soft sensors:

The Material ConneXion library is broken down into 8 different material categories:

More soon!